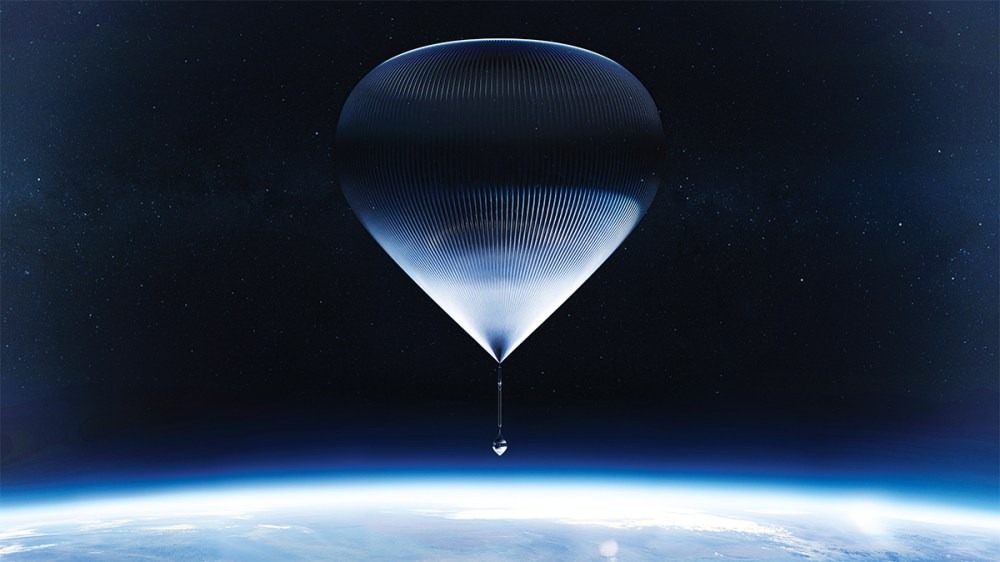

Space Perspective’s ship-based launch system for its Spaceship Neptune balloon and capsule stands out as one of the most unique and innovative designs in the aerospace industry. The system’s design, which uses Lego building blocks during its creation process, reflects the complexity and creativity involved in this remarkable project.

Taber MacCallum, co-founder and chief technology officer of Space Perspective, explained that they kept purchasing more Lego boxes as they reworked and reconfigured their mock-up of the system. The 294-foot MS Voyager, based in Florida, operates a sophisticated roller system that launches the 650-foot balloon and its passenger pod with just 200 feet of deck space. The system functions with the precision of a massive, mechanized Rube Goldberg machine, where rollers gradually unfurl the capsule’s only means of propulsion— a balloon— in a careful, zigzagging process.

“The goal is to handle the balloon gently without creating any pressure points,” MacCallum noted during a recent Robb Report tour of the ship. A small amount of hydrogen is injected into the balloon’s tip, and the rollers slowly bring the balloon upright. Once upright, it is tethered to the capsule at the stern of the ship. MacCallum explained, “We need only 1 percent of the lift gas since hydrogen expands as it rises.” By the time the balloon reaches its peak altitude of 100,000 feet, it is fully inflated, completing its ascent with the help of minimal lift gas.

While the deployment system itself is innovative, the ship serves as a significant milestone in the aerospace industry as the first-ever marine spaceport designed for human space flights. In collaboration with the U.S. Coast Guard and the Federal Aviation Administration, Space Perspective has ensured the ship complies with all regulations for this new type of vessel.

MacCallum initially dismissed the idea of using a floating launchpad but soon realized that the safety advantages of a marine platform outweighed those of traditional land-based options. With no need for parachutes during splashdown—the balloon controls the descent—the ocean also eliminates the need for precise landing spots. The onboard mission control center works in tandem with the main operations center located in Titusville, Florida, further enhancing the system’s reliability.

Michael Savage, Space Perspective’s acting CEO, emphasized the transformation of the MS Voyager, formerly an offshore supply vessel, into a luxury launch platform. “It’s still a working ship, but we’ve done a complete overhaul,” he explained, referencing the vessel’s previous use in servicing oil rigs. The ship’s two-year, $31 million refit involved modernizing its Caterpillar engines to run on low-emission biofuel, retooling the deck to accommodate large hydrogen tanks and other essential equipment, and upgrading the electronics. The ship now features luxurious additions such as offices, a medical center, suites, and a salon area for guests. Furthermore, restaurateur David Grutman, known for his upscale dining establishments like Gekko in Miami and Komodo in Las Vegas, is providing high-end culinary experiences on both the ship and within the capsule.

Voyager’s decks are staffed with a team of 15 crew members and 25 technicians who ensure that the balloon’s launch, its six-hour, 19-mile climb, and subsequent descent are all meticulously managed. The ship’s bridge is equipped with state-of-the-art servers, computers, and equipment to monitor life-support systems, thermal levels, and other vital functions within the capsule. Four satellite networks provide communication redundancy, and two rigid-inflatable tenders are ready to assist in securing the capsule until the Voyager arrives to retrieve it.

In anticipation of the debut commercial flight in 2026, Space Perspective is also preparing a larger retrieval ship capable of holding two capsules. The retrieval ship can pull a capsule out of the water within 20 minutes. MacCallum envisions a network of similar marine spaceports in Europe and Asia within the next few years. With the first uncrewed flight successfully launched just days after the tour, the floating launchpad concept is proving to be viable and effective.

As for the capsule itself, the Excelsior on Spaceship Neptune is a 19-foot-high sphere with a 16-foot diameter, offering 2,000 cubic feet of living space. This generous design allows the capsule to accommodate eight guests and a captain in a relaxed, casual environment, without the need for space suits. The interior features a lounge area with a stocked bar, Wi-Fi, recliners, and the largest viewing windows ever designed for a spaceflight, providing an unparalleled experience.

The capsule also boasts an advanced environmental control and life-support system that includes air revitalization to keep the air fresh and active heating and cooling to maintain a comfortable environment. Its conical shape ensures a smooth and stable descent, acting as a sea anchor during splashdown. In the rare event of a malfunction or balloon damage, the capsule is equipped with six parachutes to safely manage the descent.

Michael Savage explained that while the aerospace industry often focuses on minimizing weight, the Neptune capsule doesn’t have the same limitations. “We use more robust parts that can take a beating,” he said, adding that the capsule is expected to last for 1,000 flights with proper maintenance, making it an example of true sustainability in aerospace design.